Note: clicking the links below will take you to our glossary of vacuum-related terms and phrases. To return to this page from the glossary, just hit your “back” button.

Centrifugal molecular distillation (or short-path distillation) is recognized as the optimal thermal separation method for heat sensitive materials like cannabis, because it poses minimal risk of damaging or destroying the product – and Myers Vaccum is the recognized leader in centrifugal molecular distillation. The key principles behind Myers Vacuum’s stills are low pressure and extremely short residence time, both of which are absolutely essential to effective cannabanoid processing. Myers stills give you maximum purity, quality, and yield.

Why The Lab 3 Unit by Myers Vacuum Is The Best Choice For Cannabanoid Processing

The Lab 3 system, which is specifically designed to handle thermally sensitive organic compounds, is the best choice for processing cannabanoids because it has the shortest resistance time available in the market, and it maximizes yield, purity, and quality by distilling hemp and cannabis in a low pressure range (1 to 700 X 10-3 Torr).

This is crucial to efficient hemp and cannabis processing, because the lower the distillation pressure, the lower the heat required to effect evaporation, and the lower the chance of damaging or destroying the product. Lower pressure also means lower energy costs, which makes the purification process more affordable and the end product more profitable.

The Lab 3’s closed loop temperature control provides the most stable product heating in the industry, allowing separation of materials with close evaporation temperatures that cannot be processed with other units.

The Lab 3 centrifugal still uses gravity to flow the feed material from degasser to the still and then on to the collection vessels. This natural vertical flow minimizes flow time by preventing holdups anywhere along the way, and it also means there is no gear pump to power, clean, or leak.

Myers Vacuum’s Lab 3 Unit Produces Maximum Purity, Quality, and Yield of CBD and THC

Myers Vacuum’s Lab 3 unit produces maximum purity, quality, and yield of CBD and THC. The Lab 3 packs the power, efficiency, reliability, and capability of centrifugal molecular distillation into a convenient and rugged bench model that has minimal space and power requirements, but delivers maximum results.

• Complete modular design

• Easy setup on workbench or tabletop

• Easy to disassemble/assemble for cleaning

• Few moving parts, reducing maintenance cost/labor and simplifying cleaning

• Shortest resistance time in market, reducing chance of damaging product

• Closed loop temperature control provides the most stable product heating in the industry, allowing separation of materials with close evaporation temperatures that cannot be processed with other units

• Best vacuum configuration in the industry

• Easy to operate and understand system controls

• Mostly stainless steel construction with glass only as needed to observe process

• Need to increase production? Upgrading to Myers Vacuum’s Pilot 15 centrifugal molecular distillation unit is fast, simple, and cost-effective

Count on the Lab 3 for Portability, Power, and Rugged Convenience

The Lab 3 is a compact system with minimal space and power requirements. Its modular design system takes up very little space in the laboratory and allows for easy setup and moving, and because the system is primarily stainless steel with very little glass, it’s easy to clean and hard to break. All manifolds are stainless steel with standard vacuum fittings that make disassembly/assembly for cleaning fast and easy, and both vacuum pumps are built with rugged durability in mind. The mechanical pump is a direct drive rotary vane vacuum pump that’s used as a forepump (exhaust) for the diffusion (high vacuum) pump, and to rough pump the degasser, the distillation, the distillate and the residue chambers. The high vacuum pump is a heavy-duty 2″ diffusion pump that’s hardwearing and hardworking.

The Lab 3 Process For Cannabanoid Processing

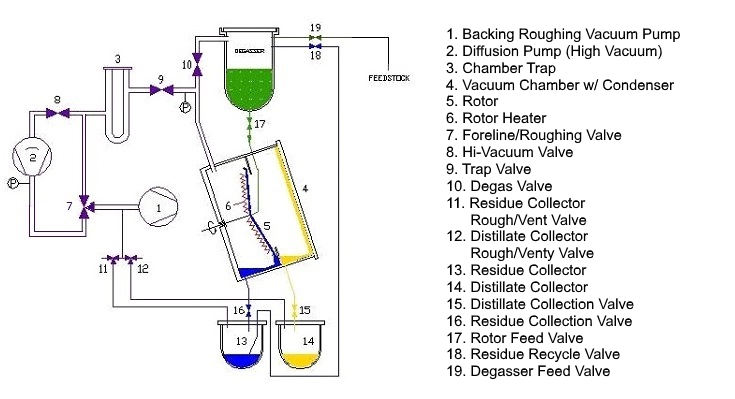

The Lab 3 flows the feed material downward in a vertical path from the degasser into the still and onto the spinning heated disc, where distillation takes place in less than 1 second (see schematic below).

The residue is caught in a gutter that surrounds the rotor, and from there it continues flowing vertically into a collecting vessel located below the still.

The distillate condenses on the outer shell of the still and flows by gravity to another collecting vessel also below the still.

The Lab 3 system is designed as a batch/continuous distillation unit, and can distill batches as small as 50ml or as large as 1 liter.

A sight port allows the operator to watch the process as it occurs.

Because the Lab 3 is a complete, fully valved system, the operator can isolate certain areas to make desired adjustments without completely shutting the system down.

Comprehensive Control Center

The Lab 3 features a state of the art control center that contains all of the controls and readouts required for operation.

The Vacuum Readout includes a 2-station pressure monitoring section with leak detect mode, for accurate pressure measurements in the distillation chamber and on the foreline. The Temperature Readout features an SCR temperature controller which enables the operator to set and control the temperature of the rotor.

The thermocouple is located inside the rotor for true film temperature measurement, and the control center also provides a variable power switch for the addition of heat tapes if desired.

Complete Lab-3 System Standard Bench Model

Part Number: 285352

Still Assembly: Includes degassing feed chamber, 3″ diameter heated rotor, water-cooled condensing surface, feed valve, distillate / residue valves, and distillate / residue collecting vessels. The residue collecting vessel is equipped with a recycle line returning to the degassing chamber for multiple pass operation. The still components are mounted on a stand and are easily accessible for cleaning and maintenance. Wetted components are stainless steel, viton seals and a minimum of glassware.

Pumping System: Includes 2″ diffusion high vacuum pump, mechanical pump, vacuum cold trap, vacuum manifold with valves, and water manifold with valves. It is mounted in a cabinet which connects to the Still Assembly via flexible hoses.

Control Center: Includes thermistor vacuum gauge, digital temperature controller, individual switches for rotation, heater mechanical and diffusion pump, and a variably switched power outlet for the addition of heat tapes.

Myers Vacuum is a recognized leader in molecular distillation. Owned and operated by a disabled American veteran, Myers Vacuum equipment is 100% American made. Years of experience and proven expertise plus a continuing commitment to precision, innovation, and outstanding customer service make Myers Vacuum the right choice when quality really counts.