The VDG-5 system is designed to remove low boiling point solvent, dissolved gas (air, moisture, etc.), and volatiles from raw feedstock. Utilizing Rough vacuum to accomplish evaporation of material at room temperatures versus conventional methods. Its batch size to up to 5 gallons makes it an ideal unit for process development and small production lots for evaluation.

The VDG-5 is a complete distillation system including all of the pumping, heating, vacuum generating and control equipment needed for operation. The small amount of floor space occupied by the unit and skid mounted design makes the VDG-5 a most attractive system. The control center features a microprocessor control unit that controls all major functions and may be interfaced to a PC.

Operation

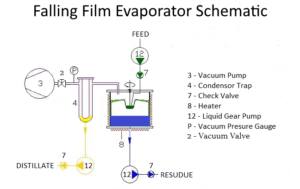

The VDG-5 is a cylinder shape heated chamber, which can produce pressures as low as 1 X 10-3 Torr. The chamber itself has a heating mantle with a temperature sensor. Feedstock is filled into chamber all valves are closed the liquid nitrogen trap is filled and the vacuum pump is turned on. At this point the chamber heater is set to an appropriate temperature. As the adjustable vacuum valve is opened part of the feedstock reaches a pressure at which it vaporizes, leaving the chamber to condense on the cooler surfaces of the cold trap. The un-vaporized feedstock or residue remain in the chamber and is drained through a residue drain valve. The condensed vapor on the cold trap flows by gravity into a removal pipe and is pumped or removed through a valve from the system. Simplicity of the chamber allows for easy disassembly and cleaning.

The VDG-5 is a batch system that contains all of the facilities for degassing raw feedstock. This unit is designed for use in development and pilot-plant work. In certain cases it can be considered a production tool.

The VDG-5 is a complete skid mounted, stand alone turnkey device that only requires electricity and a cooling medium. It has a complete control center with vacuum gauge and all necessary switches.

Specifications

Utilities Electrical: 208V single phase 4-Wire 40 Amps 60 Hz

Liquid nitrogen: consumption will be process dependent

Type: Batch

Operating Pressure: 10-3 Torr to Atmosphere

Capacity: 5 gallons max.