Lab – 3 Centrifugal Molecular Distillation System

Still Assembly, (287705)

- degassing feed chamber (420 m Liter max. volume)

- 3″ diameter heated rotor

- water-cooled condenser surface

- feed valve

- distillate/residue valves

- distillate/residue collecting vessels (465 m Liter max. volume each)

Pumping System (500707)

- 2″ diffusion high vacuum pump

- mechanical pump

- vacuum cold trap

- stainless steel vacuum manifold and valves

- water manifold with valves

- cabinet mounted

Control Center, ( 287735-1)

- Two (2) digital thermistor vacuum gauges Myers GT-430

- digital temperature controller,

- individual switches for rotation, heater mechanical and diffusion pump operation

- switched/variable power outlet for the addition of heat tapes.

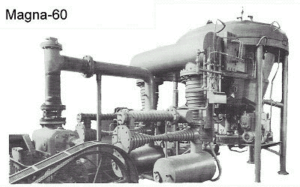

Magna 60 Centrifugal Still

- Still Assembly

- Vacuum Chamber

- With water-cooled lid with sight Ports and gutter system to remove Residue material

- Water/solvent Cooled trap with gutter system for evacuation of material

- Balanced Rotor – rotating “flower pot” shaped with four independent heat zones

- Condenser – 42 water cooled leaf condensers.

- 23 individual Calrod heater elements of 4100 watts each

- Gutter systems for separate removal of three (3) distillates, (1) drip and (1) residue out puts

- Hickman High Vacuum Pump installed or ports can be used to install KSM 2000 or other vacuum pump

Pilot-15

Complete system (includes):

- Touchscreen control

- Feed system comprised of four (4) variable speed pump gear pumps.

- Stainless steel vacuum manifolds with glass traps.

- Completely frame mounted. Powder coated frame and mounting brackets.

- Materials in contract with the process material are either 300 series stainless steel or glass.

- Stainless Steel tubing and check valves

- SCR power switching for Rotor heater, degasser feed line, degasser jacket, rotor feed line, residue removal line and distillate removal line.

- Two rotary vane vacuum pumps.

- KS-200 High Vacuum Diffusion pump.

- Distillation chamber with Rotor.

- Degasser Falling Film