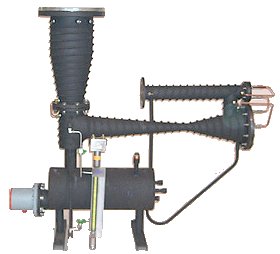

The KSM-2000 is a three stage vapor pump whose diffusion and ejector nozzles are supplied from a common electrically heated boiler.

Features

- High throughput: 2500 liters / second at 10-3 Torr range.

- Efficient heat transfer: replaceable immersion heaters reduce heat loss

- Oil Temperature monitor and oil sight level

- Foreline ejector stage allows operation at higher pressures (up to 1 Torr)

- Fast pump down times

- Cooling and quench coils

- Optional boiler insulation jacket

Applications

The KSM-2000 is a three stage high vacuum (10-3 to 10-4 Torr range) vapor pump designed for heavy gas load applications such as in vacuum distillation, evaporation, vacuum arc melting, freeze drying, impregnation and casting of metals. The pump has no moving parts which may be corroded by the acidic nature of the material being pumped. These pumps may be used in place of mechanical roots type blower pumps.

Description

The KSM-2000 is a three stage vapor pump with diffusion and ejector nozzles supplied from a common electrically heated boiler.

Two umbrella type vapor stages, positioned in the vertical column, have nozzles through which jets of vapor are emitted to entrain the gas entering the pump inlet. The compressed gas is then passed on to the ejector stage in the horizontal convergent divergent arm of the pump.

Two umbrella type vapor stages, positioned in the vertical column, have nozzles through which jets of vapor are emitted to entrain the gas entering the pump inlet. The compressed gas is then passed on to the ejector stage in the horizontal convergent divergent arm of the pump.

The pump achieves a peak operating pumping speed of 2500 liters/second at 10-3 Torr and has an ultimate pressure in the 10-4 Torr range. The ejector stage is operated at a sufficiently high boiler pressure to handle gas loads in the 10-1 Torr pressure range and also provides a forepressure tolerance of greater than 1 Torr.

The pump comes equipped with water-cooling lines with disconnect fittings and vacuum flanges which allows for easy maintenance disassembly. On board oil temperature and oil level indicators allow for ease of system monitoring during operation. Quench lines in the boiler provide rapid cooling of oil when systems operation is stopped (these connections are standard ¾” allowing for use of standard water hoses for temporary connection when needed). The external boiler which supplies the vapor is equipped with replaceable blade type immersion heaters.

An optional thermal jacket is available for the boiler housing. This will reduce heat loss and power consumption during operation. It is attached using high temperature Velcro strips. This allows for easy removal to avoid contamination by cleaning solvents and oil during maintenance.

Specifications

All data obtained with Convoil-20 pump fluid. Pumping speed measured with Convoil 20 diffusion pump.

Inlet connection: Flange

– O.D.: 19″

– Bolt circle: 17″

– No. of holes: 12

Outlet connection: Flange

– O.D. : 9″

– Bolt circle: 7-1/2″

– No. of holes: 8

Heater Voltage (Rated): 240, 480, or 550v, 3ph.(as requested by customer)

Heater Wattage (Rated): 12000w

Net weight: 780 lbs.

Shipping weight: 930 lbs.

Plateau speed (liters per second): 2500

Typical air throughput In pumpdown range (Torr-liters per second): 40

Ordering Information

KSM-2000 – Diffusion ejector pump cr. stl., water-cooled 3ø, 12KW, 230V. Immersion heater.

Part # 500385

KSM-2000 – Jet assembly

Part # 500361

Replacement heaters for KSM-2000 – 240/480V, 12 KW, 3 Phase On 6″ ASA Flange

Part # 260703

Insulation Jacket – Removeable Thermal Jacket for boiler housing

Part # 500383