Centrifugal molecular distillation is a purification technique, which has gained wide acceptance in the chemical, food processing, pharmaceutical, and petroleum industries as well as the specialty chemicals industry. The PILOT-15 utilizes this technique for pilot plant and medium production needs on a continuous basis.

The PILOT-15 is a complete distillation system including all of the pumping, heating, vacuum generating and control equipment needed for plant operation. The small amount of floor space occupied by the unit helps make the PILOT-15, in single or multiple installations, a most attractive system. The touch screen control features an easy to follow system schematic. The PILOT-15 is designed for throughputs between 10 and 80 lb/hr (4.5 to 36 kg/hr), depending on feed material characteristics.

The major advantages to be expected from the PILOT 15 molecular still are:

- High product percentage yield

- Elimination of color bodies

- Elimination of odor fractions

- Reduction of acid values in ester distillation

- Removal of excess reactants

- Elimination of residual metal catalysts

- Minimized thermal hazard (a necessity for heat sensitive compounds)

The PILOT 15 is designed to continuously distill thermally sensitive organic and silicone compounds in the molecular weight range of 150 to 400 AMU at vacuum pressures from 1 to 700 X 10-3 Torr.

Some examples of distillation from the PILOT 15 include Fatty acid amides, Dimer acids, Epoxy resins, Drying oils, Monoesters, Di-octyl phthalate, Vitamin A, and Tocoperols ( Vitamin E). For more detail listing of products and table showing distillation temperature of some common products in vacuum go to https://myers-vacuum.com/vacuum-stills/myers-still-applications/

Description

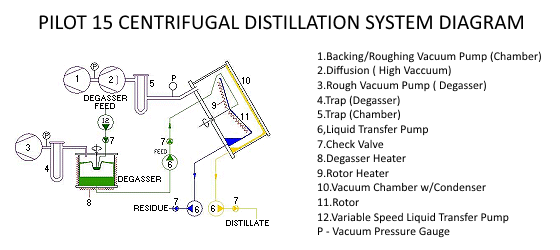

The PILOT-15 is designed to distill materials in the pressure range from 700 X 10-3 Torr down to 1 X 10-3 Torr. The lower the pressure, the lower the heat required to effect distillation. The lower the heat, the lower the chance of damaging the product and reduces the energy costs required for the purification process. The PILOT-15 has a complete vacuum system as can be seen from the diagram. Both the degasser and the high vacuum distillation chamber have vapor traps; these vapor traps are cooled by liquid Nitrogen or equitant medium. A diffusion-ejector pump and a rotary vane vacuum pump evacuate the main chamber. The degasser has a separate rotary vane vacuum pump. There are three regions of pressure monitoring. This enables the operator to get accurate pressure measurements in the three critical areas: the degasser, the high-vacuum chamber, and the fore line.

Material Handling

The PILOT-15 is designed as a continuous flow, vacuum distillation system. The diagram illustrates the flow of material through the still.

- The material is pumped from the customer supplied supply/feed tank by a variable speed feed pump (12) into the degasser.

- In the degasser small amounts of low boiling materials and trapped gases are removed to enable more efficient vacuum distillation at the next stage.

- A feed pump (6) moves the degassed material onto the center of a heated, spinning Rotor (11) in the high vacuum distillation chamber (10).

- On the Rotor the material spreads out into a thin film. As the material spreads across the Rotor, a certain portion (the distillate) evaporates. The fraction which distills is selected by the operator by adjusting the temperature. Once set, this remains constant until the production run is completed or until new conditions are selected.

- The distillate vapor condenses in the vacuum chamber on a water cooled condenser in Chamber (10) and moves to a separate liquid transfer pump and is removed from the system through check valve to atmosphere.

- The portion which does not distill, (the residue) flows off the edge of the rotor to be contained by a separate gutter and moves to another liquid transfer pump through a check valve to atmosphere.

- Depending upon the feed stock material or process requirements, either the distillate or the residue may be your final product. In many cases both may be of value.

Heating

The product path through the PILOT 15 is heated in separate zones. The zones can be temperature regulated for conditioning of the product for various steps in the process. They are the degasser feed line, the degasser wall, the rotor feed line, rotor heater temperature, distillate line and residue line.

Control Center

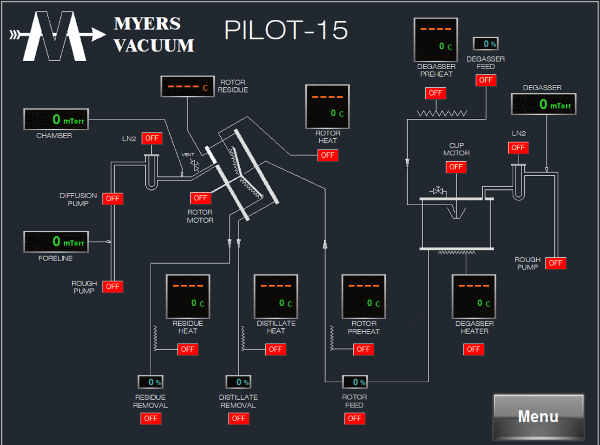

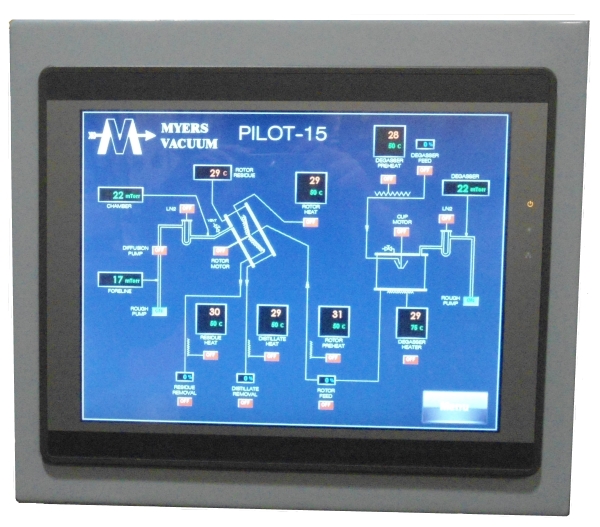

All of the readouts and controls are conveniently grouped on the control panel mounted on the still.

The control center offers displays of the three vacuum stations, the actual and set point temperatures of the degasser pre-heater, degasser heater, the rotor pre-heater, the rotor heater, residue line heater and distillate line heater.

Controls of all vacuum pumps and feed pumps are also located here.

All electrical circuits are protected by fuses.

The PILOT-15 Control Center controls and displays the following:

- Actual and set point temperature of the degasser pre-heater.

- Actual and set point temperature of the degasser heater jacket.

- Actual and set point temperature of the distillation pre-heater.

- Actual and set point temperature of the rotor heater.

- Actual and set point temperature of the residue and distillate removal lines

- Rotor residue temperature.

- Pressure of the degasser.

- Pressure of the distillation zone.

- Pressure of the pump foreline.

- Screen control changes from red to green to indicate motors and vacuum pump state.

- Control of liquid transfer pump speed.

The operator controls the process by setting the feedstock rate (How thick the material will be on the rotor) and the rotor heater temperature.

Equipment in Detail

The PILOT-15 receives process material from the customer-supplied storage tank. This material passes through stainless steel pipes through the variable speed feed pump. This pump controls the flow rate of material through the PILOT-15. From the feed pump the material passes along a length of heated pipe before entering the degasser.

Preheated material enters a rotating cup within the degasser and is spun onto the heated walls to quickly out gas the material. The media runs down and is collected on the heated base. Degassed material passes, via a pipeline, to the distillation chamber feed pump.

From the feed pump the material passes along a length of pipe, which is heated to reduce any heat lose, before entering the distillation chamber. In the distillation chamber the material is introduced onto the center of the spinning rotor disk and is spread across the heated surface. The surface area increases exponentially as material travels across the disc thus exposing more material to surface for evaporation as it travels across. The material will separate into a vapor phase, the distillate, depending on the operators’ combination choice of temperature and pressure. The remaining material is the residue.

From the feed pump the material passes along a length of pipe, which is heated to reduce any heat lose, before entering the distillation chamber. In the distillation chamber the material is introduced onto the center of the spinning rotor disk and is spread across the heated surface. The surface area increases exponentially as material travels across the disc thus exposing more material to surface for evaporation as it travels across. The material will separate into a vapor phase, the distillate, depending on the operators’ combination choice of temperature and pressure. The remaining material is the residue.

The distillate vapor is condensed on a water-cooled surface and flows down the chamber walls and out to the distillate pump. The residue passing across the full surface of the rotor is collected in a surrounding gutter and flows out of the chamber to the residue pump. On the exit of each pump is a non-return valve to isolate the distillation chamber from atmospheric pressure.

Feed, distillate, and residue storage tanks are supplied by the customer, unless specified otherwise. Both the degasser and distillation chambers have independent vacuum pumping systems which are protected with individual traps.

The traps in each vacuum line are refrigerated to protect from cross-contamination with the vacuum pump fluids. Both traps have drain taps, which are used to empty the traps while the PILOT 15 is shut down and at atmosphere. Trap collection vessels or gear pumps can be added to drain the traps while the PILOT 15 is running and are supplied as an option. The degasser vacuum pump is a direct drive rotary vane positive displacement pump with exhaust to atmosphere. The distillation chamber vacuum pumps are a diffusion-ejector pump backed by a direct drive rotary vane positive-displacement pump with exhaust to atmosphere. System pressures are monitored at the degasser, distillation chamber, and the ejector pump fore line.

Options Available

- Additional Condensing Area

- Extra traps can be added to vacuum line in series with main traps in chamber or degasser vacuum lines.

- Water Cooled Chamber walls (optional) Adds 8.1 square foot (0.75 m2)

- Trap collection vessels or gear pumps can be added to drain the traps while the PILOT 15 is running

- Stainless Steel Traps

- Glass Liquid Nitrogen traps can be replaced with Stainless steel.

- Multi coolant Stainless steel insets can be installed in above traps.

- Stainless Steel Liquid Transfer Pumps

- Chilling System to replace liquid Nitrogen required for Traps

- Flow meter to Feed, Distillate and/or Residue Lines

Standard Items Provided on the PILOT 15 Still

- Feed system: Four (4) variable speed pump gear pumps.

- Stainless steel vacuum manifolds with glass traps.

- Powder coated frame and mounting brackets

- Completely frame mounted

- Materials in contract with the process material are either 316 stainless steel or glass.

- SCR power regulators for Rotor heater, degasser feed line, degasser jacket, rotor feed line, residue removal line and distillate removal line.

- Stainless Steel tubing and check valves

- Two rotary vacuum pumps.

- KS-200 diffusion pump.

- Distillation chamber with Rotorcone.

- Degasser Falling Film

User Provided Equipment

The PILOT-15 is a very complete unit. The only external requirements in addition to power, low pressure air, and water are

- Suitable heated storage tank for the Feed Stocks.

- Suitable tanks to collect Distillate and Residue.

- Suitable cooling media for traps.

*Note: Because Myers Spinning Disk Technology replaces the material on evaporator heated surface at rate of 8 to 10 times faster than Wiped Film and similar techniques, significantly less surface area is required.