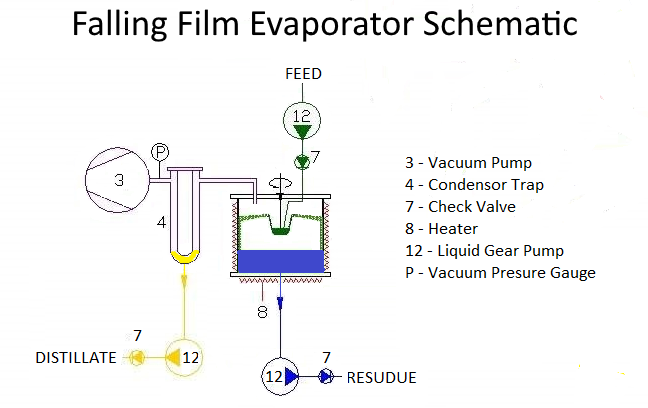

The Falling Film Evaporator is used where there is a significant percentage of moderate or low boiling distillate. Medium vacuum and an external condenser are utilized with a heated vessel.

Applications / Features

Applications / Features

- Continuous atmosphere to atmosphere operation

- Skid mounted/ stand alone/ turnkey device

- Contains all of the facilities for distilling raw feedstock.

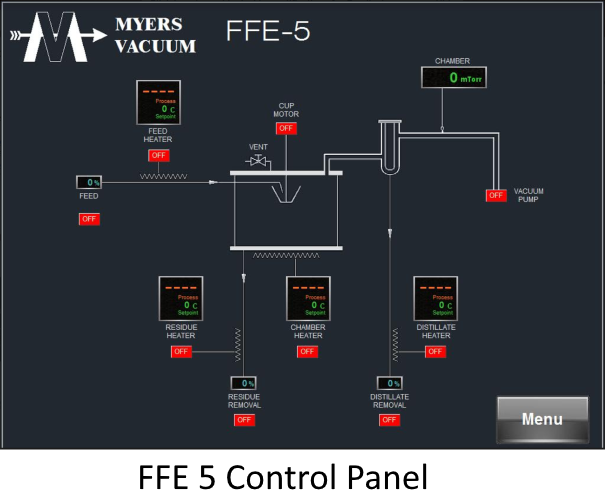

- PLC Touch Screen control/display

- A heated vacuum chamber & liquid gear pumps

- Vacuum gauge, check valves, condenser/trap, vacuum pump and controls.

- For use in development and pilot-plant work.

- In certain cases it can be considered a production tool.

- Easily disassembled for cleaning/maintenance

Description

The feedstock is spread onto the inside of the chamber walls then moves by gravity down the electrically heated chamber. The heater is controlled with a closed loop temperature controller and feedback sensor, this allows for a wide range of temperature operation. As the feedstock reaches the temperature at which it vaporizes, it leaves the chamber to condense on the cooler surfaces of the external condenser. The un-vaporized feedstock or residue flows to the bottom where it is pumped from the chamber and the condensed vapor on the cold trap flows by gravity into a removal pipe to be pumped from the system.

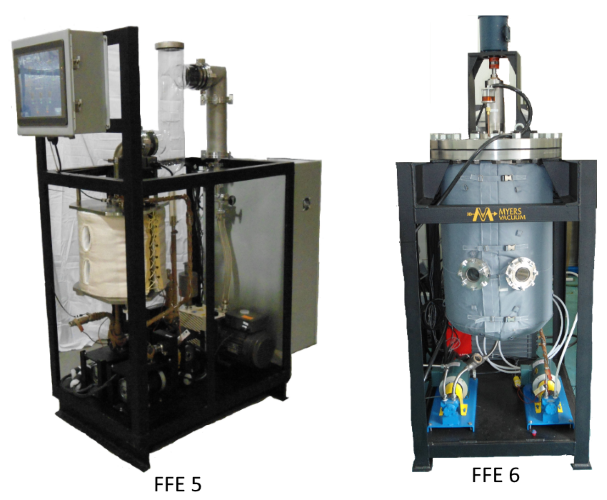

FFE-5 has a maximum throughput of 80 lb/hr

FFE-6 has a maximum throughput of 400 lb/hr

Notes:

- Maximum throughput rates are dependant on process, feed stock, etc.

- Systems can be modified for specific applications or higher throughput.