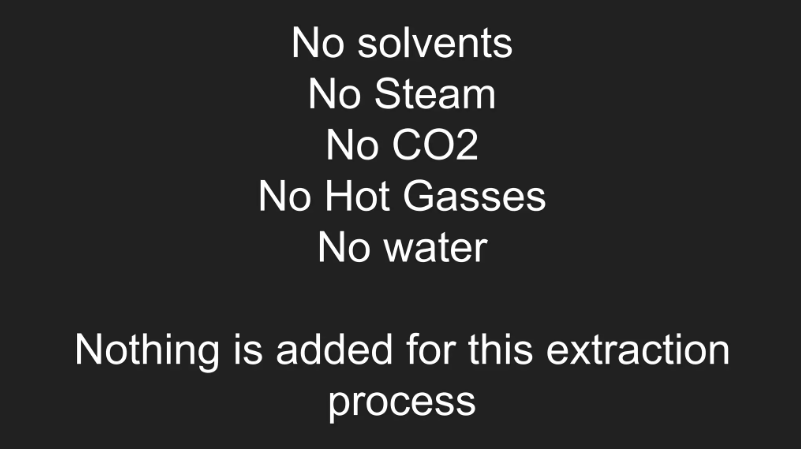

Nothing is added to the product for the Extraction Process

No Solvents

No Steam

No CO2

No Hot Gasses

No water

No High Pressure

No Press

The principle advantages of this system is NO solvent is used, only one single piece of equipment with low thermal hazard, and separate collection areas.

Material is loaded into the cylindrical chamber, the pressure is changed and energy is applied. As the material transfers the energy, the most volatile (lighter molecular weight) portion leaves the chamber to be collected, and a less volatile portion is collected internally. Time is allowed for this energy transfer to be completed and then the internal collector is removed from the chamber. The lightest material is allowed to drain from its collector, or its collector is withdrawn and the remaining plant material is removed from the chamber.

The major advantages to be expected from the SPExtR extractor are:

- Solventless

- Separate collection of light fractions (terpenes, water, etc.)

- Separate collection of intermediate fraction (cannabinoids)

- Minimized thermal hazard (a necessity for heat sensitive compounds)

- Decarboxylation

- No high pressures

- Nothing is added in the process besides the starting plant material and a collection vial.

FEATURES

FEATURES

There are several important design features that make SPExtR an outstanding tool in the laboratory:

- Simple to clean. – Mostly stainless steel with minimum glass usage

- No gear pump to clean or leak.

- Simple design allows for easy set up and moving location.

- Requires little space for operation.

- Information/process developed is easily scaled up to larger sized models.

OPERATING OBJECTIVES

OPERATING OBJECTIVES

The SPExtR is designed to separate thermally sensitive compounds in a particular molecular weight range. The system utilizes a pressure change at start then the material in the chamber is subjected to a certain amount of energy. This energy transfer takes advantage of the molecules mean free path. Once parameters are reached, time is allowed for complete energy transfer and collection occurs.

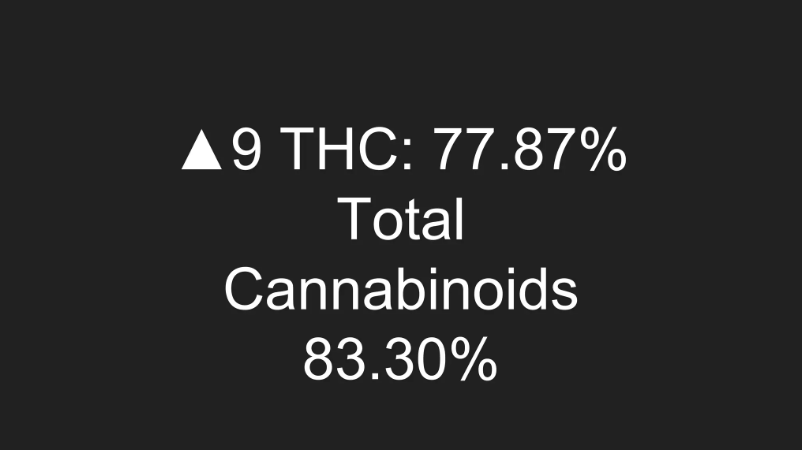

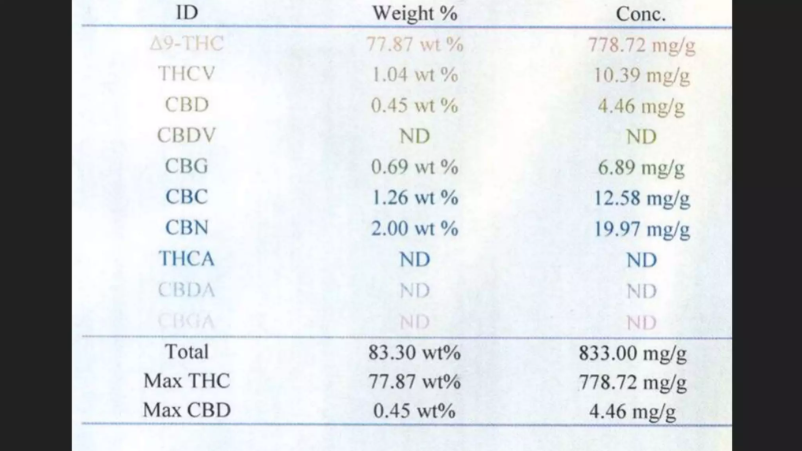

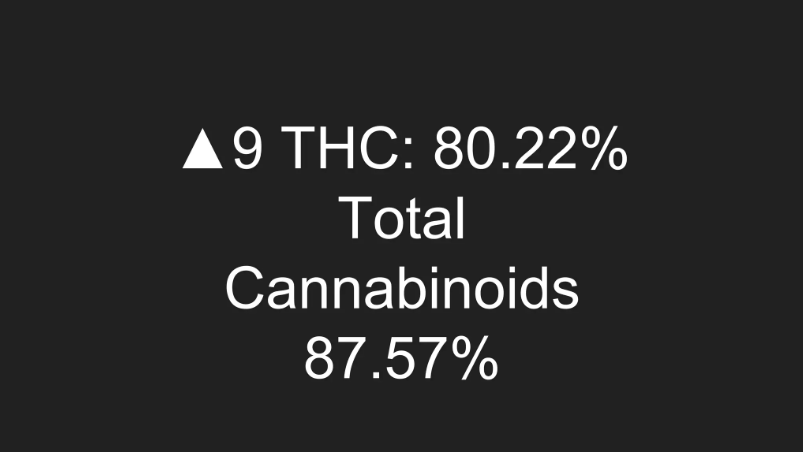

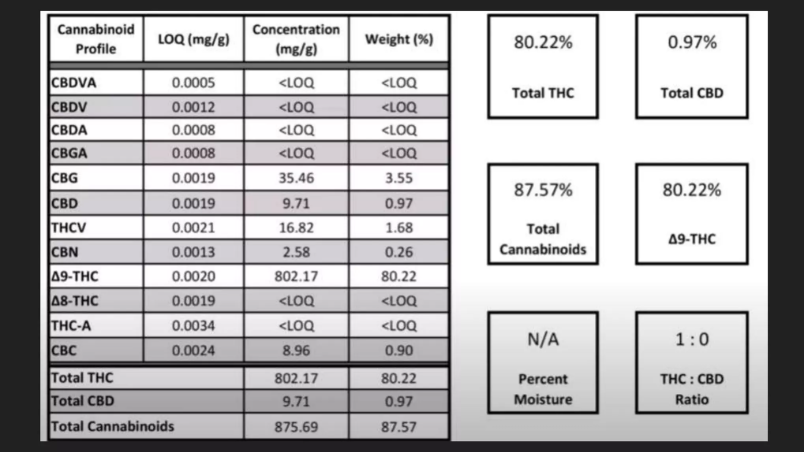

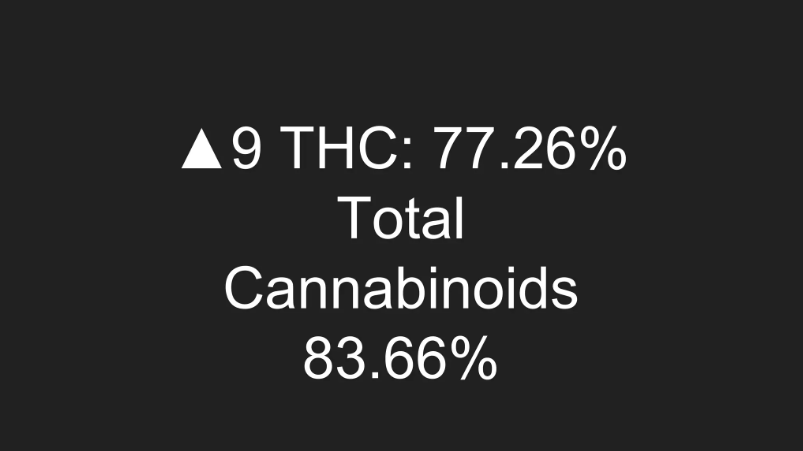

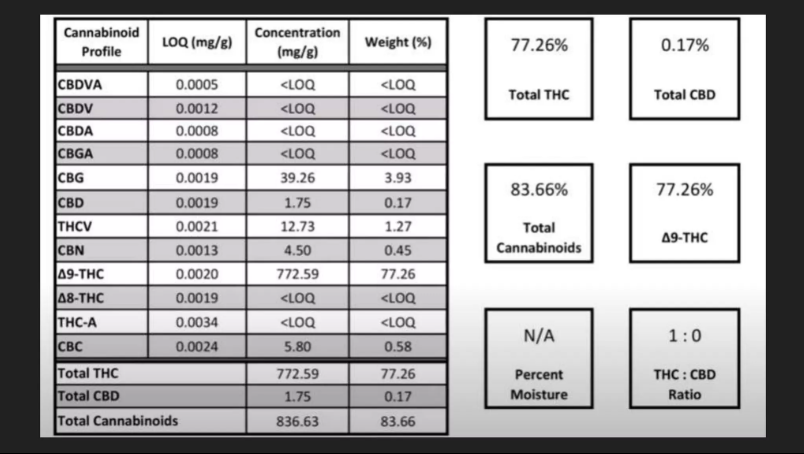

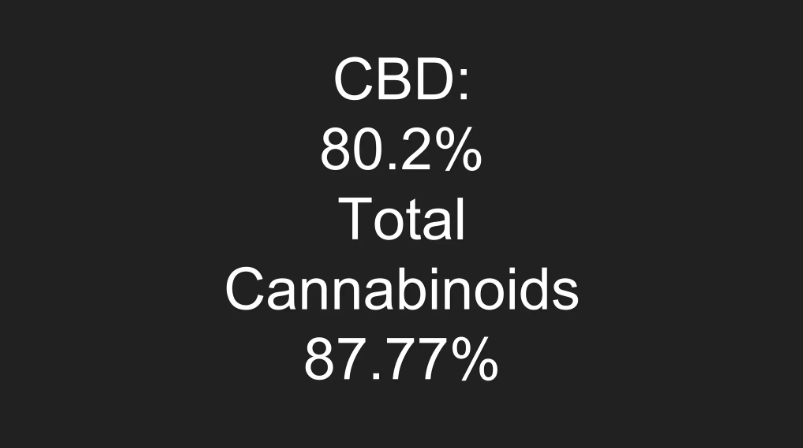

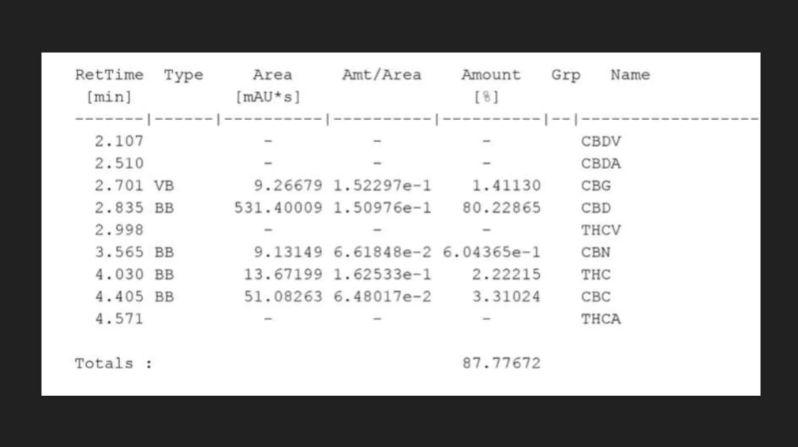

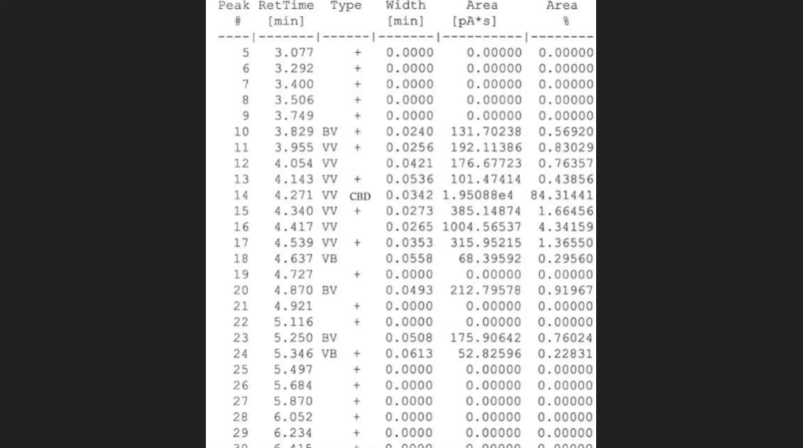

Some Reported Results

Some Reported Results

THC

THC

CBD

CBD

MATERIAL HANDLING

MATERIAL HANDLING

The SPExtR system is designed as a batch system.

- The material is loaded into the process chamber

- Liquid nitrogen is loaded and cooling water flow is started

- An isolation valve opened and system pressure reduced

- The energy input is started.

- Energy is applied to plant material and Cannabis is collected.

- Lighter molecular product collected separate (terpenes, water, etc.)

- The collection vials and left over plant material are removed

- New plant material and a new vail is then loaded and the process repeated.

The SPExtR will accept material for process that has been properly dried and is over 0.039” in size.

SYSTEM CONSTRUCTION

SYSTEM CONSTRUCTION

With the SPExtR system the processed material will only come in contact with 300 series stainless steel, Viton, Tygon (or equal), neoprene and glass.

CONTROL CENTER

CONTROL CENTER

All of the readouts and controls are conveniently grouped. On smaller systems all necessary switches along with displays are grouped together in a convenient location. Larger systems utilizes a touch screen for control.